Engineered to meet the most demanding high-pressure applications, the STH Westco Multilayer Pipe System is at the forefront of heating and plumbing solutions. Providing the ultimate durability and flexibility, this innovative system offers a comprehensive range of piping components and advantages for the professional installer.

Despite being highly durable, like any plumbing and heating installation, the STH Westco Multilayer Pipe System still requires a degree of care and maintenance.

In this short guide, our technical experts provide some top tips when installing, troubleshooting, and maintaining the system.

Installing and Maintaining the STH Westco Multilayer Pipe System

Ensure Proper Installation

Ensure that the pipes are properly installed, maintained, repaired, and replaced according to manufacturer guidelines. Follow the recommended methods for joining pipes and use appropriate fittings to prevent leaks.

Provide Proper Support

Provide adequate support for plastic pipes, especially if they are used for horizontal runs. Proper support prevents sagging and stress on the joints.

Avoid Pressure Surges

Protect plastic pipes from sudden pressure surges by installing pressure-reducing valves or water hammer arrestors. This helps prevent damage to the pipes and fittings.

Use Appropriate Tools

When working on plastic plumbing, use tools designed for the material to avoid damaging the pipes or fittings. Avoid excessive force during installations or repairs.

Proper Storage

If you have spare plastic pipes, store them in a cool, dry place away from direct sunlight. This helps prevent premature aging or deterioration.

Avoid Harsh Chemicals

Refrain from using harsh chemicals, solvents, or drain cleaners that can damage plastic pipes. These substances may weaken the material over time.

Beware of Temperature Considerations

Be mindful of temperature extremes. While plastic pipes are generally resistant to temperature variations, it’s essential to avoid exposure to extreme heat or cold. Insulate pipes in areas prone to freezing.

Carry Out Regular Inspections

Periodically inspect your plumbing system for any signs of leaks, cracks, or damage. If you notice any leaks or damage, address the issue promptly. Ignoring plumbing problems can lead to more extensive damage and costly repairs.

Keep the Area Clean

Ensure that the area around the pipes is clean and free from debris. This helps prevent physical damage and makes it easier to identify issues during inspections.

Common issues and how to resolve them

Leaks due to damaged or improperly installed connections, fittings, or pipes

Inspect all visible connections and fittings for signs of water leaks. Tighten loose connections or replace faulty fittings. If the leak persists, assess, and repair the system.

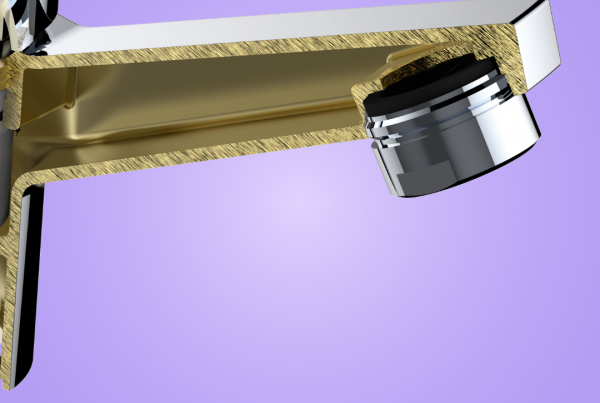

Performance issues due to clogs and build up

While plastic multilayer systems are corrosion-resistant, scaling or deposits in hard water areas can affect performance. Flush the system to remove mineral deposits. Consider installing a water softener if the issue is related to hard water. Regularly monitor and clean faucets and showerheads to prevent clogs.

Inconsistent hot water supply or temperature fluctuations

Check the water heater for proper functioning. Inspect and replace faulty thermostatic mixing valves. Ensure that the pipes are insulated to maintain consistent temperatures.

Leaks or reduced water flow

Problems with fittings or connectors can lead to problems with water flow and leakages. Inspect fittings for visible damage or signs of wear. Replace any damaged or worn fittings. Verify that the connectors are properly tightened.

Physical damage to pipes

Damage can occur during installation or due to external factors.Inspect pipes for visible signs of damage, such as kinks or dents. Replace any sections of damaged pipe. Ensure that pipes are properly supported to prevent sagging or stress.

Burst pipes

Freezing temperatures can cause plastic pipes to freeze and potentially burst. Insulate pipes in areas prone to freezing. Drain the system or use electric heating cables in extreme cold conditions.

Poor water quality

Poor water quality can impact the integrity of the pipes. Install water filters if water quality is a concern. Regularly flush the system to remove sediment and debris.

Here to help

STH Westco’s Multilayer Pipe System is engineered to exceed your expectations and provide the perfect solution for high-pressure applications. However, for maximum performance and reliability, always follow the manufacturer’s guidelines for troubleshooting and maintenance.

If you encounter persistent issues or are unsure how to address a problem, consult our technical team for assistance.

For more information, visit our website, or contact your ASM to learn how this innovative system can benefit your plumbing and heating projects.